Specific gravity for coarse, fine and sand aggregates

|

| Fine aggregate mixed with sand |

Objectives

The aim of this article is to:- Determine the specific gravity expressed as bulk specific gravity, bulk (saturated-surface-dry) specific gravity, as well as apparent specific gravity for three different samples of fine and coarse aggregates.

- Determine the percentage of water absorption for the three samples of fine and coarse aggregate after 24 hours of soaking in water.

Theory

Specific Gravity: is the ratio of the unit weight or density of solid mass, to unit weight or density of water at a specified temperature and it's a dimensionless term.Apparent Specific Gravity: is the ratio of the unit weight or density of solid mass in air of the impermeable portion of aggregate, to the unit weight or density of water at a specified temperature.

Bulk Specific Gravity: is the ration of the unit weight or density of solid mass in air excluding the voids between particles and including the permeable and impermeable voids to the unit weight or density of water at a specified temperature

Bulk Specific Gravity (SSD): is the ration of the unit weight or density of solid mass including the weight of water in the voids after submersion for 24 hours and excluding voids between particles, to the unit weight or density of water at a specified temperature

Absorption ratio: is the change in the weight that happens to the dry aggregate (dry at 110 °C in the oven) when water is added and fills the pores of the material, but not including water at the outside surface.

Part A (Specific Gravity and Absorption for coarse Aggregates)

Testing the specific gravity and absorption ratio of coarse aggregates consists of determining the weight of the sample in three conditions:

➧ Dry weight, which is obtained after drying the sample in the oven.

➧ Saturated- surface dry weight, which is obtained after soaking the sample and then drying the surfaces only.

➧ Submerged weight, which is obtained after soaking the sample in water using the wire suspended basket.

The following formulas are used to determine the specific gravity and absorption ration of coarse aggregates:

➧ Saturated- surface dry weight, which is obtained after soaking the sample and then drying the surfaces only.

➧ Submerged weight, which is obtained after soaking the sample in water using the wire suspended basket.

The following formulas are used to determine the specific gravity and absorption ration of coarse aggregates:

A= Dry weight

B= Weight in SSD in air

C= Weight of sample soaked in water

Part B (Specific Gravity and Absorption for Fine Aggregates)

Testing the specific gravity and absorption ratio of fine aggregates consists of determining the weight of the sample in three conditions:

➧ Dry weight, which is obtained after drying the sample in the oven.

➧ Saturated- surface dry weight, which is obtained after soaking the sample and then drying the surfaces only.

➧ Submerged weight, which is obtained after subtracting the weight of pycnometer filled with water from the weight of the pycnometer filled with water containing the sample.

The following formulas are used to determine the specific gravity and absorption ratio of fine aggregates:

A= Weight in (SSD) condition

B= Weight of pycnometer filled with water

C= Weight of pycnometer containing the sample and filled with water

D= Dry weight

Part C (Specific Gravity and Absorption for sand)

Dry weight which is obtained after drying the sample in the oven.

Where:

A= Weight in (SSD) condition

B= Weight of pycnometer filled with water

C= Weight of pycnometer containing the sample and filled with water

D= Dry weight

Tools and Instruments

- Container suitable for immersion of the sample and the water network cart.

- Conical Mold and Tamper

- Pycnometer Top and Glass Jar

- Drying oven: has temperature of 100 ºC.

- Balance of a capacity of 5kg and at least its sensitivity of 5g.

- Sample Containers

- Small heater

- Piece of cloth

- Water tank

- Basket of fine openings

- Wire suspending the basket

Procedure

- The samples of coarse aggregate, fine aggregate and sand were put in pots separately, and each pot had inside it small amount of water.

- The coarse aggregates were dried by using towels until they reached the saturated surface dry (SSD) condition.

- The fine aggregates and sand were dried by using electronic oven until they reached (SSD) condition.

- The weights of the SSD coarse aggregates, fine aggregates and sand were measured by using balance.

- A flask was filled with(500 ml) of water in order to measure the weight of the submerged fine aggregate and sand by subtracting (weight of flask + weight of (500ml) water) from (the flask weight + 500ml of water weight + involved sample weight).

- The weight of the submerged coarse aggregate was measured by using balance.

- The samples were put inside pots inside a big electronic oven for 2 days.

- The weights of the dry samples were measured by using a balance.

Data and Calculations

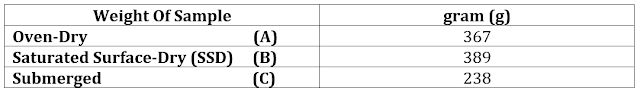

Part A: Coarse AggregateTable-1 shows the data collected to determine specific gravity and absorption rate for coarse aggregates.

Bulk specific gravity (oven-dry) = 2.43

Bulk specific gravity (SSD) = 2.57

Apparent specific gravity = 2.84

Absorption in percent = 5.99%

Part B: Fine Aggregate

Table-2 shows the data collected to determine specific gravity and absorption rate for fine aggregates.

Apparent specific gravity = 2.84

Absorption in percent = 5.99%

Part B: Fine Aggregate

Table-2 shows the data collected to determine specific gravity and absorption rate for fine aggregates.

Calculation:

Bulk specific gravity (oven-dry) = 2.50

Bulk specific gravity (SSD) = 2.66

Apparent specific gravity = 2.99

Absorption in percent = 6.68%

Bulk specific gravity (SSD) = 2.66

Apparent specific gravity = 2.99

Absorption in percent = 6.68%

Part C: Sand

Table-3 shows the data collected to determine specific gravity and absorption rate for sand.

Table-3 shows the data collected to determine specific gravity and absorption rate for sand.

Calculation:

Bulk specific gravity (oven-dry) = 2.80

Bulk specific gravity (SSD) = 2.9

Apparent specific gravity = 3.09

Absorption in percent = 3.40%

Bulk specific gravity (SSD) = 2.9

Apparent specific gravity = 3.09

Absorption in percent = 3.40%

Results and Conclusion

According to the results obtained and compared to the ASTM standards, our samples results are suitable for construction.Finally, we must be aware that there exist some systematic errors. Such errors rose when using the pycnometer due to the presence of bubbles in the sample which may affect the weight. Moreover, when obtaining saturated surface dry condition, sample surface may not be dried well and this affects the weight. Also there might be errors in reading the measurements and this is due to the fallibility of the human operator.

No comments: